lifetime of air conditioning unit

A heating and cooling system is one of the biggest investments you may have to make as a home owner. The good news is that a well maintained air conditioner can last 15 to 20 years. Regular air conditioner maintenance will not only improve the performance of your system and reduce your energy costs, it will also help to prevent costly and inconvenient breakdowns. So why wouldn’t you protect your investment and extend the life of your air conditioner by scheduling a routine tune-up? Unfortunately AC units are known to break down without warning, usually when you need them most (during the middle of the summer when it is 95+ degrees outside)! HVAC specialists will tell you that most air conditioning repair jobs could have been prevented during a tune-up. Why spend three to five times more money for a basic repair that could have been prevented during a low cost tune-up? Regular tune-ups can help to prevent a fire. Faulty wiring in your air conditioner can trip the circuit breaker and potentially start a fire.

Don’t forget that there are times when your air conditioner is running when no one is home. If your unit hasn’t been checked in years, how do you know if the internal components are working correctly? Did you know regular maintenance can help you save up to 10% on your annual energy bill? Over time an air conditioner can develop dirty coils, overheated motors and a lack of refrigerant. All of these problems can lead to major efficiency loss. An air conditioner that is not operating the way it’s supposed to be, is working harder than it should be and therefore will cause your energy bill to go up. An air conditioning tune up is something that should be done annually, ideally in the spring time. This is to ensure your system is working correctly before the heat of the summer hits and when you rely on your system the most. During a tune-up, a qualified HVAC specialist will perform a cleaning, check coolant levels, calibrate the temperatures, inspect the wiring and components, make sure the evaporator coil is clean, perform additional safety checks, and recommend any necessary repairs that need to be done.

There is no substitute for professional maintenance.

ac heat pump units for saleHowever, there are some things you can do on your own that will greatly add to the efficiency of routine professional maintenance.

ac unit running too longIn between professional tune-ups you should:

ac unit turns on by itself Now that you know why regular maintenance for your air conditioner is so important, you have no excuse to put it off any longer!This dramatic footage shows the moment an engineer risked his life to attach an air conditioning unit to the wall of a tall building.The video was shot in China and captures the fearless man holding the heavy unit while balancing on a ledge high above the ground on the inside of what appears to be a residential apartment.

Without wearing a harness and with no ropes attached to him for protection, the man side steps over the huge drop and touches down on an adjoining part of the ledge. Without wearing a harness and with no ropes attached to him for protection, the man side stepped over the huge drop and touched down on an adjoining part of the ledgeHe makes this move without being able to see where his foot is being placed and while holding the weight of the heavy metal object in his hands.He has two attempts at trying to make the move but is unable to do so adequately due to a lack of momentum in his initial step.The man settles with one of his legs on one part of the ledge and his other on the first section before he begins carrying out his work. The man settled with one of his legs on one part of the ledge and his other on the first section before he started working (left). Later he was able to move both of his legs onto the same ledge (right)Meanwhile the video maker points the camera downwards and captures the huge drop that would undoubtedly take the man’s life if he were to slip.

Later in the video the engineer manages to attach enough of the unit to the wall to free up space on the ledge for him to climb over.The clip then concludes with the man fixing the air conditioning unit in place and gesturing to the filmmaker that the job has been successful. A long way down: The video maker pointed the camera downwards and captured the huge drop that would undoubtedly take the man’s life if he were to slipThis not the first time an engineer has been filmed risking his life for the sake of an air conditioning unit in recent weeks.Late last month a workman, believed to be from India, was caught on camera swaying atop two ladders fixed together to make one huge structure.In the video the man, who was not attached to any harness, balanced against the side of the tall building, and used a drill on the unit, while the ladder moved backwards and forwards from the wall. Late last month a workman, believed to be from India, was caught on camera swaying atop two ladders fixed together to make one huge structure

As warmer weather taxes aging air-conditioning systems, the decision whether to repair an older rooftop unit or replace it with a newer, higher efficiency system may loom large for some commercial property owners.Most light-commercial HVAC products are for a life expectancy of 15 to 20 years. However, factors beyond the control of the original equipment manufacturer dictate the actual reliability and cost effectiveness of operating the equipment during its useful life period. That’s why it’s important to carefully examine each piece of equipment before reaching a decision to repair or replace a system. Understand the History of Your SystemA careful examination begins with the collection of all available information regarding the system, including records of the original installation, periodic maintenance, and repairs. If you do not have this information, contact servicing contractors and let them know you are evaluating your equipment to determine whether or not you will be replacing it.

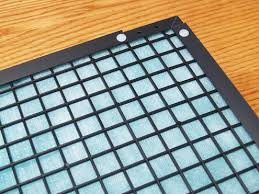

Cooperation will usually follow, and you will have the opportunity to “size up” the contractor for consideration when doing future maintenance, repairs, or replacement.If you do not have a file on each piece of equipment, start one. In addition to the records you collect, be sure to include the manufacturer’s model and serial number, individual unit or site reference numbers, installation and operating instructions, warranty information, and factory- or contractor-backed service and maintenance agreements.Overall appearance of each unit will provide valuable information about the quality and attention to maintenance provided the unit. Inspect the equipment (or have a qualified technician perform the inspection), following the manufacturer’s instructions and safety warnings before removing any access panels.The cabinetry should be intact and fastened properly to minimize any air (or weather) leakage into or out of the unit. Filters, too, should be clean. Clogged or restricted filters reduce a system’s efficiency markedly, increasing the internal negative air pressure and pulling dust, dirt, and debris into the unit’s air circulating system.

Check the condition of the coils as well, looking for evidence of dirt, debris, or physical damage to the coils. Bent, damaged, or restricted coils restrict air flow, reducing unit efficiency and increasing operating costs.Arrange for a professional contractor to inspect each unit to assess its operating condition. If you can tie this to a periodic maintenance or repair call, you will save some expense. The inspection should include a complete operating review of the and portions of the equipment and an assessment of the airflow, temperature rise, and temperature split to be certain they are within the manufacturer’s specified ratings. Be present for the inspection and request that the technician review the findings with you, including the identification of problems and recommendations and quotes for corrective actions. Include this information in the unit files you have started.Review the Information You Have CollectedAt this point in the evaluation process, you likely have learned a lot about each system.

As you review the information you have gathered, determine and confirm the applicable manufacturer and contractor-supported warranty coverage that remains on each unit. Based on the records you have and inspections conducted, assess the condition of each unit. Equipment improperly maintained and serviced is likely to be less reliable and less efficient, resulting in increased operating costs and premature failures and repair costs. Consider the age of the unit, warranties or service contracts that apply, and the condition of the unit. Has it been well-maintained and what repairs are needed in the short term and the long term?Make the Decision to Repair or ReplaceStudying current operating expenses as well as projected repair and operating expenses better equips you to make the decision to repair or replace existing equipment. Compare these expenses to the operating costs of new, high-efficiency equipment. Most manufacturers can help you make this comparison by estimating operating costs based on unit efficiency and local utility costs.

In many cases, if your equipment is aged, new high-efficiency replacements will provide significant utility savings that can be factored as a “payback” in a decision to replace.A firm quote from your contractor will help you estimate the future costs associated with restoring a unit’s operating performance. Finally, as you make your decision to repair or replace, consider applicable utility rebates for the installation of high-efficiency equipment. Your local utility can provide rebate information that applies to your area.You should also consider potential savings that new equipment warranties will provide compared to out-of-warranty repair estimates. The purchase of extended warranties and scheduled maintenance programs offer additional savings worthy of your consideration. Often these warranties can be negotiated into the initial purchase price for new equipment and offer an affordable approach to future maintenance and repairs.Select a reputable local contractor who will offer future support or backup of their workmanship.