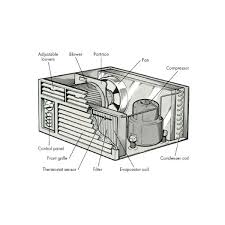

window ac unit components

This refrigeration unit has a double shaft fan motor with fans mounted on both sides of the motor. One at the evaporator side and the other at the condenser side. The evaporator side is located facing the room for cooling of the space and the condenser side outdoor for heat rejection. There is an insulated partition separating this two sides within the same casing.The front panel is the one that is seen by the user from inside the room where it is installed and has a user interfaced control be it electronically or mechanically. Older unit usually are of mechanical control type with rotary knobs to control the temperature and fan speed of the air conditioner. The newer units come with electronic control system where the functions are controlled using remote control and touch panel with digital display.The front panel has adjustable horizontal and vertical(some models) louvers where the direction of air flow are adjustable to suit the comfort of the users.The fresh intake of air called VENT (ventilation) is provided at the panel in the event that user would like to have a certain amount of fresh air from the outside.

The indoor parts of a window air conditioner include: The outdoor side parts include:During operation, a thermostat is mounted on the return air of the unit. This temperature is used to control the on or off of the compressor. Once the room temperature has been achieved, the compressor cuts off. Usually, it has to be off for at least 3 minutes before turning on again to prevent it from being damaged. For mechanical control type, there is usually a caution to turn on the unit after the unit has turned off for at least 3 minutes. For electronic control, there is usually a timer to automatically control the cut-in and cut-out of compressor.The evaporator blower fan will suck the air from the room to be conditioned through the air filter and the cooling coil. Air that has been conditioned is then discharge to deliver the cool and dehumidified air back to the room. This air mixes with the room air to bring down the temperature and humidity level of the room.The introduction of fresh air from outside the room is done through the damper which is then mixed with the return air from the room before passing it over the air filter and the cooling coil.

The air filter which is mounted in front of the evaporator acts as a filter to keep the cooling coil clean to obtain good heat-transfer from the coil.

ac units for residentialHence, regular washing and cleaning of the air filter is a good practice to ensure efficient operation of the air conditioner.

air conditioning outside unit partsHeat Pump Window Air ConditionerIn temperate countries, heating of the room is required.

air conditioner and heating window unitsA heat pump window air conditioner unit is able to cool the room during summer and heat the room during winter. A reversing valve (also known as 4-Way-Valve) is used to accomplish this. During heating operation, it reverses the flow of the refrigerant which results in the evaporator to act as a condenser and the condenser as evaporator.

If you have a Panasonic window air conditioner or you want a better understanding of how this type of air conditioner is installed, read the installation and operating instruction for model CW-XC65HU and CW-XC85HU here. Back To Window Air Conditioner Home PageHow Room Air Conditioners Work Window and room air conditioners use refrigeration principles to extract heat and moisture from room air, cooling and dehumidifying the air. The basic components inside the unit include a blower and/or fans for moving cooled air into the room and exhausting warm air, and refrigerant components for extracting heat from the air. Those components include a compressor, evaporator coil, refrigerant-filled tubing, and condenser coil. Most window and room air conditioners have thermostatic controls. How Does a Window or Room Air Conditioner Work? Room temperature reaches the thermostat’s set point, turning on the room or window air conditioner’s blower. This draws room air through the air inlet grille and a filter that removes airborne dust and particles.

Refrigerant is pumped through tubing in the unit, initiating the refrigeration process. This refrigerant takes on and gives off heat as it raises and lowers in temperature, changing from liquid to gas and then back to liquid. When the refrigerant begins to circulate through the indoor coil, it is very cold. As the blower pushes warm air across the coil, the refrigerant absorbs heat and turns into vapor. The vapor travels to a compressor that pressurizes it and moves it through the condenser coil, where it gives off heat, which is expelled outside. The refrigerant then moves through an expansion device that converts it to a low-pressure, cool liquid again, which then returns to the evaporator coil.All the while, the blower pushes air past the cold coil to chill the air and blow it back into the room.It’s going to be a hot week for many Americans. If you’ve ever installed a window air-conditioning unit in your old apartment, you know that your AC is inexplicably heavy for the small space that it cools.

It takes a lot of copper to produce all that cold air, Kelly explains. Her original piece, from 2011, is reprinted below. With temperatures rising, Americans have begun the annual summer tradition of installing cumbersome removable air conditioners. It's tough to find a window unit that's lighter than 46 pounds—and a machine like that would be able to cool only a fairly small room (150 square feet or less). What makes them so heavy?Air-conditioning systems—both centralized ones and window units—have three important components: an evaporator, a condenser, and a compressor. The evaporator helps cool the air, the condenser readies the refrigerant for the cooling process, and the compressor moves refrigerant back and forth between them. The evaporator and the condenser are both made out of copper coils, and there is some copper in the compressor, too. Copper is pretty heavy, weighing some 558 pounds per cubic foot, and the copper components account for as much as 60 percent of the weight in smaller units—though the percentage declines as they get heavier.

(Units can be as massive as 213 pounds, the weight of the heaviest window unit sold by the Friedrich Air Conditioning Co.) Steel, which provides structural support and houses or covers the compressor, accounts for the rest of the weight. Aluminum, which weighs about 169 pounds per cubic foot, could theoretically be substituted for copper. But manufacturers continue to use copper because it's a better conductor of heat. (That's important because an air conditioner works by essentially removing heat from the air.) Furthermore, the cost of an air-conditioning unit would increase if manufacturers used aluminum because of the new equipment and employee training they would have to invest in to make the necessary parts. Additionally, so much more aluminum would have to be used—to ensure that passageways in the unit were thick enough to withstand the high-pressure refrigerant moving through them—that units might not be that much lighter. Mechanical engineers aren't particularly interested in making lighterunits.