types of hvac controls

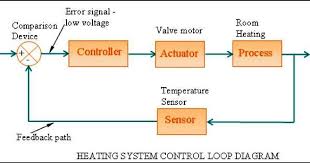

HVAC (stands for Heating, Ventilation and Air Conditioning) equipment needs a control system to regulate the operation of a heating and/or air conditioning system. Usually a sensing device is used to compare the actual state (e.g. temperature) with a target state. Then the control system draws a conclusion what action has to be taken (e.g. start the blower). Central controllers and most terminal unit controllers are programmable, meaning the direct digital control program code may be customized for the intended use. The program features include time schedules, setpoints, controllers, logic, timers, trend logs, and alarms. The unit controllers typically have analog and digital inputs that allow measurement of the variable (temperature, humidity, or pressure) and analog and digital outputs for control of the transport medium (hot/cold water and/or steam). Digital inputs are typically (dry) contacts from a control device, and analog inputs are typically a voltage or current measurement from a variable (temperature, humidity, velocity, or pressure) sensing device.

Digital outputs are typically relay contacts used to start and stop equipment, and analog outputs are typically voltage or current signals to control the movement of the medium (air/water/steam) control devices such as valves, dampers, and motors. Groups of DDC controllers, networked or not, form a layer of system themselves. This "subsystem" is vital to the performance and basic operation of the overall HVAC system. The DDC system is the "brain" of the HVAC system. It dictates the position of every damper and valve in a system. It determines which fans, pumps, and chiller run and at what speed or capacity. With this configurable intelligency in this "brain", we are moving to the concept of building automation. More complex HVAC systems can interface to Building Automation System (BAS) to allow the building owners to have more control over the heating or cooling units. The building owner can monitor the system and respond to alarms generated by the system from local or remote locations.

The system can be scheduled for occupancy or the configuration can be changed from the BAS. Sometimes the BAS is directly controlling the HVAC components. Depending on the BAS different interfaces can be used. Today, there are also dedicated gateways that connect advanced VRV / VRF and Split HVAC Systems with Home Automation and BMS (Building Management Systems) controllers for centralized control and monitoring, obviating the need to purchase more complex and expensive HVAC systems.

my air conditioner unit is making loud noiseIn addition, such gateway solutions are capable of providing remote control operation of all HVAC indoor units over the internet incorporating a simple and friendly user interface.

ac unit can't keep up It was natural that the first HVAC controllers would be pneumatic since engineers understood fluid control.

what do i do if my ac unit freezes

Thus, mechanical engineers could use their experience with the properties of steam and air to control the flow of heated or cooled air. After the control of air flow and temperature was standardized, the use of electromechanical relays in ladder logic to switch dampers became standardized. Eventually, the relays became electronic switches, as transistors eventually could handle greater current loads. By 1985, pneumatic controls could no longer compete with this new technology although pneumatic control systems (sometimes decades old) are still common in many older buildings. By the year 2000, computerized controllers were common. Today, some of these controllers can even be accessed by web browsers, which need no longer be in the same building as the HVAC equipment. This allows some economies of scale, as a single operations center can easily monitor multiple buildings. ^ Role on DDC Systems in Building CommissioningWhat you will learn from this Building Automation Systems article:the efficiency and conveniences Building Automation Systems add to a buildinghow Building Automation enhances energy savings and troubleshooting problemshow allowing controllers to communicate with each other enhances HVAC and electrical systemsmany of the benefits of Building Automation SystemsResource and Related Links to help you learn moreMany people wonder what Building Automation Systems (BAS) can do.

BAS is mainly used in commercial HVAC control systems and energy management system applications. Building Automation itself is an energy management system which saves management companies and building owners by efficiently controlling air conditioning and heating comfort and process systems.Building Automation Systems | HVAC ControlBAS is where mechanical and electrical systems and equipment are joined with microprocessors that communicate with each other and possibly to a computer. This computer and controllers in the building automation system can be networked to the internet or serve as a stand-alone system for the local peer to peer controller network only. Additionally, the BAS controllers themselves do not need a computer to process the control functions as the controllers have their own internal processors. Related Link: Learn more about DDC control loops (opens in a new window)Engineering the ControlsA set-up in a multi-story automated building would have many building automation controllers serving different types of air conditioning and heating equipment (BAS is not limited to just HVAC applications).

Every building is different and it is important for the BAS engineer to select the proper HVAC control system and programs to control the various types of HVAC systems in a particular automated building. For building automation systems to be effective, it is important that the BAS systems are installed and tuned properly. Some advantages of a good building automation system are:Basic ListBAS should allow the owner to set up schedules of operation for the equipment and lighting systems so that energy savings can be realized when the building or spaces in the building are unoccupied.BAS should allow the equipment optimal start with adaptive learning. Optimal start is allowing the equipment to be brought on in an ordered and sequential manner automatically on a schedule before the building is reoccupied so that space set points can be realized before occupation. Adaptive learning allows the system to compare space temperature, outside air conditions, and equipment capabilities so that the equipment can be turned on at an appropriate time to ensure space set points are achieved before occupation.

BAS should have trim and respond capabilities. Based on zone demand the set point for various heating and cooling sources will change according to demand from the zones. In a VAV system all the VAV boxes are served from a central air handling unit. If all the zones are at set point then the supply air temperature set point of the air handler is automatically changed to prevent mechanical cooling from occurring when it is unnecessary. When the zones grow warmer the supply air temperature set point is automatically lowered to allow mechanical cooling to satisfy demand. Older systems have a single supply air temperature set point of 55° Fahrenheit which requires the compressors to cycle even when it is not necessary.BAS should have the ability to monitor energy usage including the ability to meter electric, gas, water, steam, hot water, chilled water, and fuel oil services.BAS in conjunction with the appropriate mechanical system set-up should offer economizing based on enthalpy calculations and/or CO2 set point control.

BAS should have such BAS control algorithms as reset schedules for heating plants, static pressure control, and other systems where energy savings can be realized through these predictive programs.BAS should offer load shedding when power companies are at peak demand and need business and industry to cut back on power usage to prevent brown outs. Building Automation Systems allow the owner to cycle various things off like water heaters or drinking fountains where use of these things will not be noticed even though they are off.BAS should offer the ability to send alarms via email, pager, or telephone to alert building managers and/or technicians of developing problems and system failures.Management companies who acquire a good BAS can have the system set up to bill tenants for energy usage.BAS should have the communications abilities to be integrated with other building automation control systems and TCP/IP. BACnet compatible or other open source communication protocol is a plus.HVAC Control - ConclusionThere are many other examples of how BAS can help you especially if you manage large building(s) even if the buildings are next door to each other or on the other side of the world BAS can be linked to a central computer over the internet.