project report on air handling unit

Cookies help us deliver our services. By using our services you agree to our use of cookies Choose a country and browse our extensive product range Saint Kitts e Nevis Saint Vincent and the Grenadines Sao Tome and Principe Chiller plant control with active optimization system Know beforehand how the unit will operate once installed Explore the heat pumps range that satisfy all the heating requirements of residential, small and medium office Overview of products and systems INTEGRA multiuse units for 4-pipe systems TECS Chillers with magnetic levitation compressors Technologies for Green Data Center efficiency High precision air conditionersi-ACCURATE Climaveneta approach to service Find your nearest service center Visit the virtual cities and explore the most prestigious Climaveneta's projects around the world Climaveneta @ CAPE TOWN Technical Documentations - Regulation (EU) N. 813/2013 New European regulation ErP NRVU

Installation, use and maintenance manuals Instructions sheets and AccessoriesFind AHRI Certified® Central Station Air-Handling Unit Supply Fans.

air handling unit price list india Related Standards: 430 (I-P) and 431 (SI)

ac unit motor hot Product-Specific Operations Manual 2016

electricity unit calculator for ac AHU-DS1 (AHU Data Form) Complete this form for each AHU specification sheet verification request and send to Mary Opalka. A copy of the output sheet from the manufacturer’s Selection Rating Software must be submitted in conjunction with this form. All fields must be completed prior to submission. Only the supply fan performance (bhp and RPM) is verified. Please allow ten (10) calendar days for AHRI to conduct verification and respond to your request.

The certification program includes: A Central Station Air-Handling Unit is factory-made encased assembly consisting of a fan or fans and other necessary equipment to perform one or more of the functions of circulating, cleaning, heating, cooling, humidifying, dehumidifying and mixing of air. It shall not contain a source of cooling or heating other than gas or electric heat. The AHU shall have a maximum design external static pressure (ESP) greater than 1.0 in H2O [0.25 kPa]. While the ESP for a specific application may be less than 1.0 in H2O, any units generally capable of delivering greater than 1.0 in H2O ESP shall be considered to be an AHU. This certification program applies to supply fan ratings for plenum fans in a cabinet with a full face opening axial discharge, fan arrays in a cabinet, housed centrifugal fans, and axial fans. The rules and procedures for obtaining and maintaining certification are detailed in the Resources section above. The specific Standard listed above details the technical requirements for rating and publishing your product performance, the AHRI General Operations Manual (OM) details the program operational rules that are generic to all of AHRI’s certification programs and lastly, the Product-specific Operations Manual provides the operational rules that are specific to this program along with the required documents and fees.

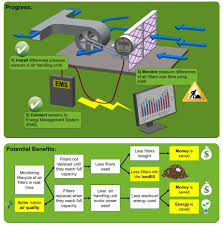

Please ensure that you are familiar with the latest rules and procedures for this program. Modeling of Air handling Unit for Wireless Monitoring August 15, 2014 through P3 Awards: A National Student Design Competition for Sustainability Focusing on People, Prosperity and the Planet (2014) The main goal of this project is to achieve a reduction in energy consumption through air handling unit (AHU) system performance improvement while also considering occupant comfort level. The objectives are to: 1) identify the key parameters of the AHU that can be efficiently, accurately, and thoroughly enhanced in a building’s energy assessment; 2) develop the wireless energy performance and consumption monitoring system (WEPCMS); and 3) improve energy efficiency with reference to ASHRAE Standard 90.1-2010, Energy Standard for Buildings. The project will be conducted by students under faculty supervision (PI) of the IUPUI Industrial Assessment Center (IAC). The project will consist of two phases.

Phase I: The wireless monitoring system, which will enable remote, real-time, sub-system monitoring, will be created at IUPUI. Phase II: The selected air handling unit (AHU) will be continuously monitored in real-time; the data will be analyzed using the algorithms developed for the system. The process model of the AHU will be developed and the major parameters will be monitored and display remotely. Best-practices will be recommended based on the collected data. Phase I: Development of the WEPCMS The WESPCMS will operate at three levels. The top level resides in a control room equipped with computer and smart controller. The middle level will be in the building where the sub-system is located. It has a wireless mesh network that consists of a PAN coordinator and at least one Router Repeater. The third level will be at the sub-system, consisting of various sensors for measuring key data characterizing system performance and energy consumption. Many third party devices have already been qualified to work with the wireless system for digital data transmission.

The system has the sensors to collect performance data. The data will be sent wirelessly to the PAN coordinator directly or through a Router Repeater. The data will be further pushed to the smart controller via Ethernet and be stored in the computer. The sub-system can also be monitored real-time using IP cameras. Actions can be taken through the system to remotely control the sub-system if needed. The data from these sensors will be analyzed for performance evaluation and energy consumption. Algorithms will be developed specifically for analyzing sub-system data. Software will be written for implementing the algorithms, tabulating the results, and displaying them on a dashboard. This project requires both hardware and software development. Phase II: Implement WESPCMS on an Air Handling Unit We have identified a sub-system and an Air Handling Unit (AHU) in Science and Engineering building as the system for this pilot project. This AHU is a large energy consumption unit and has been in service for 23 years.