motor for ac unit

United States of America Thank you for your inquiry and interest in ABB.We will get back to you as soon as possible. An error occurred and your inquiry could not be sent.Please try again later. Please select country from the list Bearings, units and housings SKF Motor Encoder Unit - the new generation Robust and reliable solution for your motor control Combining bearing and sensor functionality in one unit, sensor bearings can be integrated in AC induction motors to allow precise speed and direction control. Thanks to their compact size, these sensor bearings can help to save space in electric motor designs. The new generation of SKF Motor Encoder Unit offers a much more robust and cost-effective solution. The sensor bearing is protected from the effects of power surges and electromagnetic fields to avoid electronic failures, resulting in a reduction of maintenance and warranty costs. Robust reliability and support Combined, these integrated sensor protection features mean the new generation of SKF Motor Encoder Unit offers more reliable performance and longer service life than conventional sensor bearings.

Available for 30 mm shaft diameter, this sensor bearing can be installed at either bearing position of AC induction motors. SKF Motor Encoder Unit product tables AC induction motors in:HVAC Systems use the blower motor to feed warm and cold air to the rooms of your house year round. The only time they don’t seem to be working is for a few months in the fall and spring when the weather is mild enough to not need heating or air conditioning.

best brand of air conditioner units Because they work so often they need to be made to run for many hours before replacement is necessary but like all things eventually you will need to have your furnace serviced.

ac heating units prices There are two parts to the fan in your heater..

ac unit on its side

the motor and the fan cage. The fan cage almost never gets damaged to require replacement but the motor that drives it can have a variety of problems that all motors run into. You can have worn contact brushes, a bad bearing or a shorted armature. If you could obtain the brushes for your motor the cost would probably be under $15 for the brush set but you will need to remove the motor, remove the cage fan from the motor, disassemble the motor and install the brushes. Once you have the motor off of the fan cage it is almost always best to just go ahead and replace the motor. In almost all furnaces the motor can be replaced with a generic equivalent. Generic motors are used not only for the furnace but also for your external air conditioning unit. The rating and size of the motor should be on a label on the motor. You can visit your local electrical supply house that serves the HVAC industry or you could possibly purchase the motor online if you can wait for delivery.

Waiting in the summer is not that much of a problem but in the winter you don’t want your house to get cold and your pipes to freeze. If you don’t think that you can perform the work yourself then you can hire a HVAC Technician. Labor for HVAC repairs can be expensive. Although the work is not normally that difficult if your heating unit is located in a basement with lots of room you can expect to be charged at least a full hour but most likely 2 hours labor. If the company sends two techs you could even end up paying twice as much in Labor. That is not really reasonable but I have seen it happen. The cost per hour will depend where you live but you can expect to pay $60 per hour or more. You should ask about labor costs before the technician visits your home. Ask if there is a 1hr minimum and if they bill in hours or if they bill in quarter or half hours after the first hour. Also if you call at a time of day other then normal working hours you will probably pay a premium.

Weekends and Holidays are also a premium. The extra fee could be equal to more then an hour of labor. Oil heaters are normally feeding a baseboard hot water system however oil heat also requires a motor to feed the furnace with air to allow the oil to burn. Although the systems are different the same premise exists. You have a motor and a fan system. Some fans are of the squirrel cage type and others are propitiatory. But luckily the motors are also available in generics. Replacing the motor on an oil heat furnace should take no more then an hour and the process is pretty easy. The only hard part about replacing an oil heat furnace fan motor is that the motor also runs the oil pump. It can be a little tricky but the install is not impossible for the average home owner who is not rushed to heat a freezing home. Fan systems on Oil heaters are often referred to as inducers. So you can do the work yourself if you can get the part in a reasonable amount of time.

It is probably good to call around your area or ask at your local supply center now before you need one and ask about generics and how to spec the motor size, volts, speed, amps. In the end you should not have to pay more then about $350 to $500 maximum for a new blower motor but if you have a oil delivery service contract then they should cut you a break and the lower end of the scale should be your maximum. If a company tries to make you pay $1000 for a motor and starts telling you your circuit board and a whole bunch of other things are wrong then call someone else. Unfortunately there are not that many companies that provide this service so hopefully you will get a rival and they will be more then happy to satisfy you to get your business away from a competitor.Will a 240 Volt AC Motor Operate on 120 Volts AC Power EquipmentMarch 12, 1998 Honda Develops New Energy-Efficient, Home-Use Equipment Tokyo, March 12, 1998 --- Honda Motor Co., Ltd. announced today the development of both a compact, lightweight home-use "absorption-type heat pump air conditioner" and a "home-use cogeneration system" together with the GF160V gas-powered engine to serve as their power source.

Home-use absorption-type heat pump air conditioner This world's first ultra-small absorption-type heat pump air conditioner for home-use relies neither on electricity nor Freon. Work centered on the development of the best refrigerant/absorbent combination for use in an absorbent-type air conditioner. Using air as the cooling medium, we have been able to develop a system with a weight and size adapted to home applications. It is suited to cold climates and also functions as a heat pump heater. Running on either natural gas or LPG, this newly developed unit is the smallest gas engine in the world with a capacity of 163cc. Compactness, low noise, clean exhaust and long life make it the power source of choice for home-use gas heat pump air conditioners, and cogeneration systems. This cogeneration system can serve either to supply hot water or generate electricity. Using the GF160V gas engine as its power source, it achieves 80% energy utilization and is the first in the world to offer dimensions allowing home applications.

Besides its very high-energy conversion rate, it can also serve as a source of electricity, to help meet peak electric power need during the season of high demand. These new technologies will be displayed in Twin Ring Motegi's Fan Fun Lab scheduled to open to the public on March 21, 1998. 1) World's smallest home-use absorption-type heat pump air conditioner World's first ultra-small absorption-type heat pump air conditioner for home-use relies neither on electricity nor on Freon. Non-crystallizing, highly corrosion-resistant trifluoroethanol (TFE) coolant and high-boiling-point dimethylimidazole (DMI) absorbent are used in place of Economical air-cooled system (no water consumption). World's first heat pump heater capability using an absorption-type system. Aluminum used throughout the system for low cost, and reduced dimensions and All-year-round 3-mode air conditioner (automatic mode selection function). Absorption-type heat pump air conditioner cycle of operation

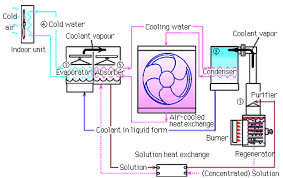

Heated by the burner, the coolant/absorbent gas mixture separates within the Coolant vapor enters the condenser and liquefies upon contact with the cooling water coming from the air-cooled heat exchange. The coolant in liquid form is sent into the evaporator where the difference in pressure helps it turn into vapor. The cold water created by the evaporation process is drawn into the indoor unit to serve as a cooler. The coolant vapor is drawn from the evaporator into the absorber, liquefies again upon contact with the absorbent coming from the regenerator and is warmed up in the solution heat exchange on its way back to the purifier. The system functions as an air conditioner (cooler) as this cycle is repeated. Apart from the heat energy provided by the regenerator's burner, the system is self-contained as the liquefaction/vaporization process is promoted by the indirect air-cooling created by using the difference in temperature with the outside.

Mode 2: Heating (1) Upon the actuation of a valve, the cooling water warmed by the condenser and absorber is drawn into the indoor unit, turning the heat pump air conditioner Mode 3: Heating (2) Whenever outside temperature falls below 0o, the burner turns into a direct heater unit warming up the water drawn into the indoor unit. The system automatically selects the most appropriate of the three modes depending on outside temperature and the temperature selected inside to offer all-year-round Heating power (heat pump) External unit dimensions (L x W x H) (mm) 800 x 250 x 680 2) World smallest gas-powered engine "GF160V" The power source of choice for home-use gas heat pump air conditioners and cogeneration systems, this newly developed GF160V is the smallest gas engine in the world. Lean-burn combustion for clean exhaust emissions with low NOx content. Multi-chamber intake silencer, large-capacity air cleaner, and high rigidity

design for low noise and reduced vibrations. Minimum life of 20,000 hours (about 10 years of average use*). Large capacity oil tank and long-life spark plug for maintenance reduced to every 6,000 hours (or about 3 years average use*). *As per the home-use gas heat pump air conditioner Compressor located right above the engine for a vertical-type** engine layout. ** Vertical-type: The cylinder is set horizontally so the crankshaft axis is in a vertical position. By opposition the engine layout with a horizontal crankshaft axis is called horizontal-type. Gas heat pump air conditioner: Instead of the usual electric motor, a gas-powered (city gas- [13A] or LPG-powered) engine is used to drive the compressor of the air conditioner unit. Research in this direction is conducted to reduce peak electricity power need during seasons of highest demand. GF160V gas-powered engine specifications: 4-stroke horizontal single cylinder OHV