how to install air handling unit

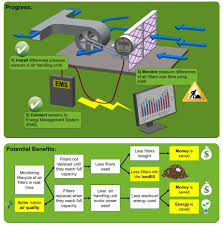

Air Handling Unit Transmitters Project Lead: Karen Lobo Sponsor: Physical Plant-Campus Services Project Theme: Energy Conservation & Efficiency Project Description: Install MS Magnesense Differential Pressure Transmitters on air handling units in eight campus buildings. These switches will notify PP-CS’s Energy Management System when filters are reaching the end of their life cycles and need to be replaced. Using the switches will end the current method of relying on scheduled replacement dates and human observation, which are often incorrect and lead to the replacement of filters that still have lifecycle remaining. Goals: Order and install new air filters only when EMS has been notified by the MS Magnesense Differential Pressure Transmitters. This project hopes to realize the extended life cycle of air filters for a time space of 50% greater than the current method. Savings include energy, human labor, purchase and transportation of new filters, and disposal and transportation of old filters.

Furthermore, data loggers installed at each location will measure Amp and voltage needed to calculate energy consumption and monitor decreased usage. This project will also help with LEED credit application and compliance with CalGreen code for indoor air quality. TGIF Blog Posts about Air Handling Unit Transmitters Project was delayed due to difficulty hiring a student intern and the project received TGIF approval for a timeline adjustment. Purchased the project equipment: 6 Differential Pressure Switches Data Loggers Filters and Conduit. 2 installed at California Hall. 3M vs. Filtrite (both mini pleated filters). Testing two different types of filters against each other to see which one has the longest life cycle - new filters will reduce labor costs, landfill waste, vehicle gas for traveling to the location. Using the Energy Management System to monitor pressure drop on filters on a monthly basis. 2 installed at Koshland Hall. Mini pleated vs. bag/ring combo filters.

Hired student intern Ace Haidrey. Stationary engineer Mike Schefers will work with Ace on the project; Mike will provide Ace with education, advising, and mentorship on energy and HVAC. Next Steps: Project will focus on installations at Bechtel Hall, as well as the on-going monitoring of the equipment results. Met with filter vendors and evaluated filters for the test sites. Walked Bechtel Hall to prep the site for installing the Differential Pressure Switches. 2 installed at Bechtel Hall. Filtrair vs Tridem filters. 1 installed at Barker Hall. Working to see if collaboration with Zero Waste Research Center is possible. Researching companies who will pick up used air filters for recycle. Future Plans: The project hopes to continue in the next academic school year, 2013-2014. The next steps for this project include the accrual of data in the next year for each of the buildings and to continue to monitor them throughout the year. Data to be collected:

Will measure the amplitude and voltage of filters, which will provide quantifiable metrics to calculate the energy consumption.

how to clean window unit air filter Create charts and graphs illustrating the savings in dollar amounts.

no filter in ac unit Create figures to represent the elongated lifecycles of the filters.

how much for a new furnace and ac unit Compare the filter price vs. the actual lifespan. The Green Initiative Fund (TGIF) provides funding for projects that reduce UC Berkeley's negative impact on the environment and make UC Berkeley more sustainable. TGIF will allocate funds to projects that promote sustainable modes of transportation, increase energy and water efficiency, restore habitat, promote environmental and food justice, and reduce the amount of waste created by UC Berkeley.

Portions of the fund also support education and behavior change initiatives, student aid (via return to aid), and internships. TGIF is supported by student fees and administered through a student-majority committee and a program coordinator.VENTUS Born in the USA Air Handling Unit – maximum features in standard unit without added costs. VENTUS Born in the USA AHUs offer ready-to-install convenience in a compact, lighter-weight air handling package, featuring an innovative frameless casing design, free of thermal bridges and air leakages. In addition, the unit’s Plenum fan features a highly efficient motor with VFD and ensures silent operation thanks to innovative airfoil blades with unique trailing edge shape. Wide range of application: Available in nine nominal capacities from 800 to 8500 CFM. Operation in different climate conditions (-40 °F to 150 °F). Horizontal and vertical configurations. Application: schools, hospitals, offices, stores Download catalogue Watch movie

Ready to install – Plug&Play device: Factory-mounted controls and end devices. 1 WEEK delivery time. Corrosion resistant and thermal-bridge free casing. Corrosion resistant drain pan made of stainless steel. Optimal selection of the unit size according to building requirements. The high quality construction of VENTUS units results from state of the art technology and following the strict international standards of quality. Energy recovery systems ideally suited to any climate conditions Minimal airstreams exchange in the energy recovery blocks Sensible and latent heat recovery realized on Energy Recovery Wheel VENTUS born in the USAmay be supplied with: direct drive PLENUM fans Smooth performance regulations using VFD technology High efficient direct drive - elimination of V-belt transmission Carefully selected and programmed control applications enable of air ventilation and conditioning circuits. The mechanical and operational characteristics of VENTUS AHUs meet the highest ratings stated by international certification programs.