high side of ac unit

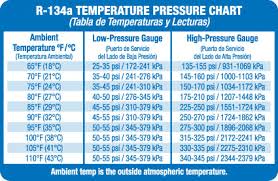

Motor Vehicle Maintenance & Repair I just did my first automotive AC repair, after the compressor in my 2004 Lancer 2.0 ate itself, cracked its casing, and blew all the refrigerant out. I think I did the repair & recharge correctly-- and the AC is blowing very cold-- but I'm concerned that the operating pressures are not anywhere close to what they are spec'd to be. (During recharge, I added ~18oz of r134a, per the yellow sticker under the hood.) Before recharging, I googled 'r134a pressure chart', and found the following: At the time, it was 82F in my garage, so I was expecting to end up in the middle of the range (both low- and high-pressure) for the 80F row.... 45psi for low, and about 190psi for the high side. (When referring to this chart, I assumed that the target low readings were for when the clutch was disengaged, and the target high readings were for when the clutch was active.) However, after my recharge the highest low reading I see (right before clutch engages) is 40psi, and the highest reading I ever see for the high side is 150 (right before the clutch disengages.)

Should I be concerned about these low operating pressures, given my starting ambient temperature? This car is 11 years old, and so the computer & pressure switch have about 160K miles on them. As I said, AC appears to be working very well. The compressor clutch cycles about 12 seconds on, and 12 seconds off.

ac unit heater not working(I'm not sure what's an exceptable duty cycle there.

cost of a new heating and air conditioning unitAlso I was parked in a garage, not running down the road, air flow through the condenser wasn't exactly real-world.

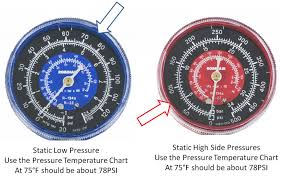

mobile home hvac repairOf course the fans kicked on whenever the clutch engaged.) Static pressures (with engine off): 80-85 for both high and low sides. In case anyone has questions about my methodology, this is what I did:

Remove old compressor, condenser, dryer, and expansion valve Flush lines and evaporator with recommended flush solvent Installed (all new) compressor, condenser, dryer, and expansion valve, coating all rubber seals with PAG oil Added UV dye and 1.75 oz of PAG-46 oil to condenser (compressor came pre-filled with 3 oz, and total required by manufacturer was 4.75) (Mitsubishi originally called for 'SUN PAG-56', but after-market compressor called for PAG-46, so I used the latter) Connected hi/low gauge set Pulled vacuum to almost -30psi, observed that level held for 1 hour Resumed pulling vacuum for 1 additional hour Closed off high & low sides, detached vacuum pump, attached 12oz can of r134a (no additives) Pierced first 12oz can, allowed yellow line to pressurize. Burped yellow line @ the manifold to purge air 12oz can+valve+hose weighed 20.7oz at this point Opened up low side, allowed vacuum in system to suck in some refrigerant

Started car, resumed slowly-turning can... compressor clutch engaged for the first time pretty early into this step. After first can felt empty, new weight reading was 8.2 (so, 12.5oz discharged from 1st "12oz" can) Closed off low side Disconnected yellow hose from can's adapter, then connected to different adapter already installed on 2nd can (at this point, I realized I had made a minor mistake, should have moved the first adapter over to the second can without disconnecting the hose. But I compensated for this by burping the yellow line again.) Initial weight of second (partial) can+adapter+hose: 15.1oz Final weight of second: 9.6 (so, 5.5oz discharged from 2nd "partial" can) Total estimated charge: 12.5+5.5=18oz (actually a little less because of burping and final contents of hoses. I think this is OK because the service manual's specifications page gives an acceptable range of "16.93 - 18.34") That chart is not universal. You should be fine.

Every model will have its own characteristic low-side and high-side pressures. This is why some manufacturers recommend charging refrigerant by mass rather than by high-side, low-side and ambient temperature values. As long as you have charged the system with the correct amount of refrigerant (which you have according to the tolerance defined in your manual), you should be fine. Another sanity check is that the low-pressure switch activates at 32 psi, which is lower than the 40 psi you are seeing on the low-side. I'm not sure if your Lancer is equipped with a high-side pressure switch but the same principle applies. Enjoy your ice-cold AC! Some observations about your procedure: This tells me that there are no leaks. Added UV dye and 1.75 oz of PAG-46 oil to condenser The UV dye is added if you want to detect leaks with UV light. Else it shouldn't be necessary. PAG-46 is the right oil for your car and is absolutely necessary to since it lubricates the internals of the compressor.

This car is 11 years old, and so the computer & pressure switch have about 160K miles on them. Not sure about the Lancer, but on some vehicles the pressure switch is a capacitor where the refrigerant pressure controls the distance between the two plates, thereby altering capacitance and voltage. Once again, the level of detail provided in this question is stellar. I'd consider this to be the golden standard for all AC-related questions.Browse other questions tagged ac pressure or ask your own question.« [Appliances] Dishwasher water line help • need some concrete slab information » TXAG@108.95.150.xCould my AC unit not be working properly I am wondering if one of my AC units is not functioning properly. I had recently installed a new thermostat (in a different post/topic in the forum) and after initially installing, it seemed that it was taking a long time for the room to cool down. This particular room is a remodel/finish out over my garage so it's prob some 400-500 sq ft. and Coleman unit is less than 6-7 yrs (previous owners installed).

I apologize, but I don't know the tonnage of the unit but have attached a picture of the label on the side of the condenser.My problem was that after installing the thermostat, it said the inside temp in that room was 82 (The outside temp was between 93-94) and it seemed to take more than 30-45 min to cool the room down 4 degrees to 78. In trying to trouble shoot the problem, one thing I noticed when comparing this unit's performance to the one for my upstairs and downstairs was the temp of the air coming out the vents. I used one of those laser/infrared thermometers and measured the air coming out of the vents for the unit I'm concerned about measuring 62-65 (4 diff vents in the room) with a room temp of 77 whereas the air output for my other units measured 53-54 degrees also for a room temp of 77. I went outside and made sure I rinsed the grate/fins on the condenser. The air filter is probably 2 months old. The "freon" line feels cold while the unit is running. If I remember, this room used to cool down pretty quickly before since it essentially has its own AC unit.

The condenser to this unit seems to run very quietly. Almost like the quietness of desk or floor fan. The other units seem to make more noise while running….ie i can hear them running when I am outside the house and even around the corner of the house.Do outside condensers make a certain level of motor noise when operating appropriately?I had a capacitor replaced last summer on my upstairs ac unit and when the technician was running/testing the unit after changing the capacitor, he noticed it was running pretty quietly and he went and made some adjustment and the motor noise became louder or noisier. I am hoping some of you HVAC guys will know what I am talking about or referring to (what a normal condenser is supposed to sound like or how noisy it should be).I guess I am going to have to call a company to come out. I'm not sure why the temp diff of air going into the unit (using room temp of 77) and air temp coming out the vents (Mid 60's) is so small. Especially compared to my other units which have closer to a 20 degree differential.

I don't know if it will be a matter of just needing to add more freon (R410) or something else. The unit seems to maintain the room temp and cycles no more or less frequently than my other units.Are there any suggestions or other things I should do to trouble shoot the problem before calling someone out? Original Thermostat with red wire to RcNew One with red wire to RCInside Furnace/blowerNot that it probably matters, but I said I had a Coleman A/C Unit. It is actually a Goodman. Notexactly positive what a heat pump is. All I know is it is a single stage cooling and gas fired furnace for heat. I checked again tonight and the air coming out is mid to high 60's and air going into the air return was 74 with room temp on thermostat reading 78.In regards to the thermostat install, I believe I connected it correctly. The original thermostat had 5 wires Blue ©, Y, G, W, R(installed in Rc). I connected the same way as shown in 2nd pic. I am wondering about the R vs Rc now??Inside the furnace/blower the red wire is connected to R (there is no Rc).

Sorry for poor quality pic. However the original thermostat (honeywell) had the red wire installed to Rc (jumper from Rc to R) which is why I chose to install in the Rc connection. Isn't the Rc connection to power the transformer for cooling purposes? Plus with leaving the jumper in place for R and Rc would it matter whether the red wire was connected to the Rc vs the R??The unit seems to be cycling appropriately as far as frequency and now that it has cooled room (currently set at 78 for the night) is seems that its run time is "normal". My concern initially was how long it took to originally cool the room from the 82 to 78 this afternoon, but now it is bothering me that the air blowing out doesn't seem to be cold enough (by measurement).This is confusing me. If the thermostat turns on and off the unit as temp in room goes up and down, but the air coming out is too warm (for normal operational specs), could this be a thermostat problem, blower/furnace problem, or condenser problem (i.e. coolant)?

Thanks pende_timPremium Memberjoin:2004-01-04Andover, NJkudos:1· Unit I'm having trouble withUpstairs unit that works greatThanks for the reply. Removing the panels on the air handler was something I did as a last thing when I was curious about the wire connections on that end. So most of my "warm air" or low temp differential problems I've been trouble shooting were prior to removing anything other than the thermostat off the wall. None the less, I'll recheck the panels on my blower to make sure I did reinstall them securely.I did also go out and check the lines going into the outdoor unit and compare to my others. When this unit is running it does "sweat" and feel cold. It doesn't subjectively feel as cold as on my other units, but this may be normal since it is a smaller unit (smaller tonnage) compared to my other ones.In fact, for kicks and grins, I used my non contact infrared thermometer that I've been using to test the air coming out of my ceiling vents to also test the temp of these lines.

I'm not sure how useful or accurate this method is above and beyond seeing that the line has condensation and feels cool/cold to the touch. The outdoor air temp is currently 80 and on the unit I'm concerned with, the temp of the "suction line" ranged between 69-75 depending on exact laser point location. The longer it ran the more consistent the readings were in the mid 70's. On my upstairs unit the (outside) suction line had temp readings in the mid 60's while running and my downstairs unit was fairly consistent at 70-71 (not pictured). Point being, the suction line does get cold and sweat, but should it, can it, or does it need to be colder?(I did clean the debris, leaves, mulch from around the inlet lines to make sure that wasn't causing the problem)I also want to double check and ask whether in my case does it matter whether I have that red wire hooked up on my thermostat to the Rc or R terminal? Like I previously mentioned, I chose the Rc terminal b/c thats where it was connected on the thermostat I replaced.