air handling unit section

H/HL Air-handling units of series Swimming pool. H/HL – AIR-HANDLING UNITS OF SERIES SWIMMING POOL Swimming-pool air conditioning units H/HL are specially designed for ventilation of the in-door public, school, hotel, family swimming-pools as well as baths and other facilities with high air humidity. The units provide for central air distribution, conditioning and dehumidification, i.e. filtering, warming and recuperation. The Swimming-pool air conditioning units are compact or modular units of the square/rectangular cross section. Air-handling and air-conditioning units of series H/HL swimming-pool are compact or modular units of square/rectangular section designated for air central distribution, treatment and dehumidification, i.e. for filtration, heating, heat recovery and dehumidification in roofed public, school, hotel and private swimming-pools, baths and other premises with high air humidity. The sections are assembled from filet closed Al-angles that have surfaces forsealing peripheral panels.

The angles are connected by corner Al-brackets. The connection is made by pressing on and is secured by riveting. The rigid panels are fixed by riveting from inside, the service panels are pressed by clamps or screwed from the section outside. The orifices for regular maintenance are fitted with doors.The panel is assembled from two steel galvanized troughs that are peripherally riveted together by single-ended rivets; the outer panel wall is made of varnished sheet. Inside the panel there is insulating filler from Orsil material with specific weight of 100 kg/m3 and degree of flammability B. Panel thickness is 25 mm. Index of the panel air soundproof is R = 41 dB, heat-transfer coefficient is k = 1.55 Wm-2K-1.The protective zinc layer on the panel sheet is 275 g/m2 at minimum. In case of special demand it is possible to supply units with panels made from stainless sheets on the internal side. Doors are made from modified panels and are fitted with hinges and locks.The fan-motor set with V-belt drive is mounted on the common frame, which is made from special profiled Al-bars.

The set is spring-mounted on the section structure by means of rubber blocks. The fan discharge and section wall are interconnected with flexible insert. The suction and discharge openings of the unit are fitted with flexible insert for connection to a pipeline.The cooling circuit of the heat pump is sealed, the used coolant R407C is environmentally friendly. The unit with heat pump is equipped with extremely silent sealed spiral compressor Copeland – Scroll.Electric switchboard with a control unit is an inseparable part of the air-conditioning unit. It includes microprocessor regulation and power circuits and it is located on the unit side; if required by a customer, it may be supplied separately for placement on a machine room wall. Types of units H/HL for swimming pools: • With plate recovery excharger – R • With double plate recovery – RR • With heat pump – T • With plate recovery excharger and heat pump – RT • With double plate recovery and heat pump – RRT

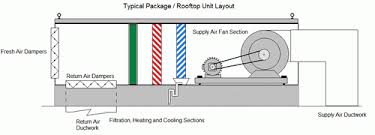

The PREMI-AIRE air handling unit is modular in concept. Each section can stand alone or be coupled to adjoining sections in a variety of different ways thus providing the most effective and flexible installation features possible. Composite construction is an alternative cost effective option on smaller models. All sections provide maximum access for general and major maintenance. Each section can also (as standard) be provided with base drainage to facilitate total cleaning and customer hygiene regimes.

stand up ac unit cheap The PREMI-AIRE �AA� series of air-handling units provides maximum flexibility of selection within the standard* model range.

ac power supply ukThe reference suffix �AA1, or AA1.5 and AA2 relate to the unit overall cross-section aspect ratio.

window ac unit for cheap

For example �AA1 is as wide as high and �AA1.5 is one and a half times wide as high etc.The prefix numbers broadly relate to the unit nominal air volume (dependant upon coil velocity).Therefore with the exception of the beginning and end of the model range it should be possible to select at least two, if not three alternative aspect ratios from the standard series*, allowing the best option to be selected for the application and location.The standard* range covers air volumes from 0.5 m3/s through to 25.0 m3/s. However, very much larger and to a limited extent smaller air volumes can be accommodated. *Standard models may be modified to suit space limitations etc., without the penalty of �special unit� costing. Despite there being a standard range all PREMI-AIRE air-handling units are bespoke, designed and built to the customer�s specific requirement. Units may be manufactured for external location, provided in a fully weatherproof format including a separate, naturally ventilated roof designed to reduce solar gain impact.

The standard panel and framework core insulation is Styrofoam, expanded polystyrene, which is light, yet rigid and structurally strong. It has been safely used within the building industry for over 40 years.The air-handling unit panels are laminated on inner and outer faces with food safe Stelvatite, but other facing materials may be substituted. Styrofoam has excellent thermal performance, being far superior to mineral wool or fibreglass alternatives. Alternative insulation materials are available to suit the application.The most common for lower or higher temperature projects is PIR, a rigid foam insulation based upon phenolic resin Any form of filtration can be incorporated from the basic G4 disposable panel filter through to the highest efficiency HEPA. Stainless steel washable mesh filters are also available to collect grease or to provide foundation filtration in dusty/dirty conditions where disposable filters would be changed too frequently. Odour control may be achieved using activated carbon filters and air sanitization by a suitable UV system.

The PREMI-AIRE air handling unit can incorporate any form of heat exchanger from the conventional finned coil through to direct or indirect gas heat exchangers. Conventional finned coil coolers are mounted in a specific section, which is provided with a separate extended stainless steel drain tray.This tray features a two-directional fall to the outlet drain connection, thereby ensuring continuous �dry� operation without pooling.The coils are mounted on runners for ease of withdrawal and sealed to a bulkhead, preventing any air by-pass. Heaters either finned coil, electric or indirect gas, may be included in the heat exchanger section, or in other sections as required. Forward curved, backward curved, heavy duty backward curved and plug fans are secured onto purpose designed, rigid, all welded, hot-dipped galvanised steel frames, which in turn are mounted on high efficiency, enclosed spring anti-vibration mounts.This arrangement ensures quiet and vibration free operation. Fans may be belt or direct driven and all drive motors are suitable for inverter control.