air handling unit project

YORK® Custom Air Handling Units (AHU) The YORK® Custom Air Handling experience is designed to adapt effortlessly to the unique needs of every environment, providing perfectly balanced performance by matching AHU features and efficiency against the precise demands of a building. The new experience begins with a streamlined manufacturing process to accelerate project cycles and increase the speed to installation. Injected Foam Insulation improves thermal performance while providing a stronger and lighter unit structure Ultra-Thermal Break Construction includes a unique floor-to-base thermal break that eliminates exterior sweating on the entire unit housing Fan System Redundancy ensures greater uptime while using fewer fans and non-proprietary parts Streamlined Manufacturing Process accelerates project cycles and increases speed to installation Acoustiweir™ Technology reduces sound levels and controls vibrations while maintaining a compact unit footprint

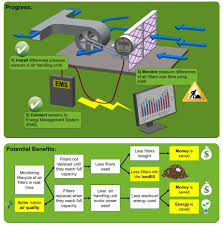

Factory Controls reduce project installation time through intelligent manufacturing and streamlined controls systems YORK® Airside Technical Services offer total-system post-sale services and support by knowledgeable application experts Tailored Flexibility ensures your AHU is never limited by your environment or our production processAir Handling Unit Transmitters Project Lead: Karen Lobo Sponsor: Physical Plant-Campus Services Project Theme: Energy Conservation & Efficiency Project Description: Install MS Magnesense Differential Pressure Transmitters on air handling units in eight campus buildings. These switches will notify PP-CS’s Energy Management System when filters are reaching the end of their life cycles and need to be replaced. Using the switches will end the current method of relying on scheduled replacement dates and human observation, which are often incorrect and lead to the replacement of filters that still have lifecycle remaining.

Goals: Order and install new air filters only when EMS has been notified by the MS Magnesense Differential Pressure Transmitters. This project hopes to realize the extended life cycle of air filters for a time space of 50% greater than the current method.

heating cooling portable unitsSavings include energy, human labor, purchase and transportation of new filters, and disposal and transportation of old filters.

pop up ac unit for saleFurthermore, data loggers installed at each location will measure Amp and voltage needed to calculate energy consumption and monitor decreased usage.

rv roof ac unitsThis project will also help with LEED credit application and compliance with CalGreen code for indoor air quality. TGIF Blog Posts about Air Handling Unit Transmitters

Project was delayed due to difficulty hiring a student intern and the project received TGIF approval for a timeline adjustment. Purchased the project equipment: 6 Differential Pressure Switches Data Loggers Filters and Conduit. 2 installed at California Hall. 3M vs. Filtrite (both mini pleated filters). Testing two different types of filters against each other to see which one has the longest life cycle - new filters will reduce labor costs, landfill waste, vehicle gas for traveling to the location. Using the Energy Management System to monitor pressure drop on filters on a monthly basis. 2 installed at Koshland Hall. Mini pleated vs. bag/ring combo filters. Hired student intern Ace Haidrey. Stationary engineer Mike Schefers will work with Ace on the project; Mike will provide Ace with education, advising, and mentorship on energy and HVAC. Next Steps: Project will focus on installations at Bechtel Hall, as well as the on-going monitoring of the equipment results.

Met with filter vendors and evaluated filters for the test sites. Walked Bechtel Hall to prep the site for installing the Differential Pressure Switches. 2 installed at Bechtel Hall. Filtrair vs Tridem filters. 1 installed at Barker Hall. Working to see if collaboration with Zero Waste Research Center is possible. Researching companies who will pick up used air filters for recycle. Future Plans: The project hopes to continue in the next academic school year, 2013-2014. The next steps for this project include the accrual of data in the next year for each of the buildings and to continue to monitor them throughout the year. Data to be collected: Will measure the amplitude and voltage of filters, which will provide quantifiable metrics to calculate the energy consumption. Create charts and graphs illustrating the savings in dollar amounts. Create figures to represent the elongated lifecycles of the filters. Compare the filter price vs. the actual lifespan.

The Green Initiative Fund (TGIF) provides funding for projects that reduce UC Berkeley's negative impact on the environment and make UC Berkeley more sustainable. TGIF will allocate funds to projects that promote sustainable modes of transportation, increase energy and water efficiency, restore habitat, promote environmental and food justice, and reduce the amount of waste created by UC Berkeley. Portions of the fund also support education and behavior change initiatives, student aid (via return to aid), and internships. TGIF is supported by student fees and administered through a student-majority committee and a program coordinator.mercial Facility with Unusual LayoutA Lombard, IL commercial building plagued with high energy bills chose to upgrade to a high efficiency air handling unit on the fourth, sixth, and seventh floors of the high-rise building. The problem: the mechanical room was in the center of an office filled with employees on the sixth and seventh floors. With the need to upgrade the system, but without disrupting business, this commercial business chose F.E. Moran Mechanical Services as the lead contractor to coordinate the difficult task.

Numerous Hurdles Conquered over Holiday WeekendDue to the location of the mechanical rooms, this project was certain to have obstacles. The first, F.E. Moran had to install a new air handling unit in the center of two occupied floors without disrupting business or disturbing the facility. To solve this problem, the installation was scheduled over the Thanksgiving holiday, to avoid disturbing employees. However, this tight timeline posed its own difficulties. The F.E. Moran Mechanical Services crew now had to tightly coordinate the installation and all sub-contractors scheduled work to ensure all work was complete before employees arrived Monday morning. The dismantling of the old air handling system posed a new problem. The old air handling unit was built in 1982. It was so large it needed to be dismantled piece by piece to remove it, and the mechanical room needed to be re-structured. The original air handling unit was obtrusive, providing only a foot of space for service personnel to work.

Additionally, a vestibule was inside the already small mechanical room, and needed to be taken down without disturbing employees or blemishing the building.The final hurtle was moving the new air handling unit onto the sixth and seventh floors without disturbing the building. With the issue of moving a large air handling unit and an additional problem of only having passenger elevators to move it in, the team needed to think outside of the box. Creative Thinking Provides Solid SolutionsF.E. Moran Mechanical Services was hired as the lead contractor, putting them in charge of coordinating all sub-contractors. Mr. Maloni made a color-coordinated schedule for all contractors, detailing when and where each contractor needed to be. Mr. Maloni worked around the clock the days before the project began to ensure perfect coordination and set-up, ultimately resulting in only two hours of sleep between Tuesday and Thursday. Contractors worked from Tuesday morning to Sunday evening, working straight through Thanksgiving.

The crews celebrated Thanksgiving together with turkey chili delivered the morning of Thanksgiving by Mr. Maloni's wife.To move the air handling unit into the building, three foremen, Mike Jones and Chris Waprairski of Mechanical Services and Mike Strezo of F.E. Moran, built a custom dolly that angled the pieces of the air handling unit into an arrangement that fit into the passenger elevator without scuffing walls, floors, or ceilings. The team built mock up equipment to test paths and angles to ensure the interior remained flawless. In the F.E. Moran shop, the air handling unit was dismantled for passage. The custom dolly seamlessly transported the unit without issue.Now, the team had to rebuild the air handling unit in the tight mechanical room. To do this, the team added temporary structural beams above the actual structural beams and used them to hoist the 3,000 pound equipment using chain falls into the air to piece the air handling unit together like a puzzle. Mr. Maloni described it as, "building a ship in a bottle."

Mission Accomplished in Six DaysF.E. Moran completed the project in six days. By Monday morning, employees entered their offices without incident. The sixth and seventh floors were clean and back in working order.Now the commercial facility had a new, energy efficient air handling system with a smooth, non-disruptive installation. The new air handling unit had many benefits. It was much smaller than the original, providing usable room in the mechanical room for service. An added bonus was the energy efficiency. ComEd gave the facility an $8,900 rebate, to be taken directly off their energy bills, as a benefit of having an energy efficient system. While the old system had 2 compressors, the new air handling unit had scroll compressors with a variable frequency drive that gave a smaller electrical pulse when the unit wasn't needed, reducing energy bills and usage.F.E. Moran Mechanical Services has been providing HVAC mechanical services for commercial facilities for more than twenty years.