air handling unit measurement

“This project was the culmination of over 12 months of product review, trials, testing, life cycle analysis and presentation to our directors and regional centre managers, so it was fantastic to see this go ahead” says Adrian Napper, Hornsby’s Facilities Manager. Purpose of the project Energy is one of Scentre Group’s key focus areas as we aim to manage our assets as efficiently as possible. Using energy more wisely in our buildings help Scentre Group manage operational costs and maintain outgoings for tenants. On average, 65% of energy consumed in shopping centres is used for cooling and ventilation purposes. Therefore, improving energy efficiency can generate significant benefits for Scentre Group and the environment. Energy management and efficiency has been identified as a key priority in our Sustainable Business framework and strategy. Since 2014, a cross-divisional team have been working together to reduce the energy consumption and carbon footprint of Westfield shopping centres.

The group, chaired by the GM National Facilities & Sustainability and the GM Design Projects, includes engineers and facilities managers who incubate innovative solutions aimed at improving the long-term performance of assets. The Horsnby shopping centre was selected to run an initial trial and to measure the benefits of implementing a UV treatment technology in existing air handling units. The trial involved installing UV lamps in the air conditioning units in order to keep the equipment free of dust and bacterial agents. This allows the air to move through the unit more efficiently as it remains cleaner. The treatment also avoids repetitive maintenance throughout the lifecycle of the plant. The UVC Coil Treatment technology delivered the expected energy savings and was deemed successful. This led to the approval of a business case to complete the roll-out of the technology across the remainder of the centre” explains Nick Morse, National Facilities Manager. Installation across the centre was complete in June with Sterile Aire installing 250 UVC emitters throughout 37 Air Handling Units.

Following the success of the Hornsby roll-out early 2015, National Facilities sought approval for installation of UV treatment technology to air handling units at other Westfield centres” says Nick.

large wall unit air conditionersBusiness cases were approved and projects initiated end 2015 at six additional centres.

how to fix my central air conditioning unit“UVC emitters are also now included as standard in our specification for new air handling units” explains Barry Robertson, Senior Mechanical Engineer.

through the wall hvac unit Independent consultant JCM Solutions mandated by NSW Department of Environment and Heritage measured and verified results concluded that energy savings of over 20% reduction from HVAC intensity, at 95% confidence, were identified in the Bondi Zone B.

These savings are primarily attributed to the UV installation . Based on independent measurement validation and verification at Bondi, the technology has resulted in 20% annual reduction in cooling demand which equates to circa 360,000 kWh for the site representing the equivalent annual consumption of 62 Australian average households. This equates to an equivalent emission saving of 339 tCO2-e per annum. More in Case Study SMART Blue, Smart Buildings, Smart Business, PGIM LatAm greenbuilding internal certification system Next-generation Eco Store – Smart AEON Can the Marriage of Big Data and Sustainability Help Bankers Avoid Another CRE Debacle? ESG Performance in Australia and New Zealand: the Heat Is on Real Estate Lenders Are Ready for Change Climate Change Readiness in Canadian Real Estate: A Snapshot What Obama, the Real Estate Sector, and 130 Investors Have in Common Hold Your Horses – 3 More Days until the Release of the 2016 GRESB Data

Real Estate Just Got Its Own Industry Classification – It Deserves Its Own ESG Rating Next-generation Eco Store – Smart AEON Home > Commercial HVAC > Measuring Commercial Equipment Static Pressures Measuring Commercial Equipment Static Pressures Commercial rooftop equipment is probably used the most in commercial applications today in most regions of the country. Packaged equipment 7.5 tons and larger offer some unique challenges of their own that you should be aware of to avoid erroneous readings. Static pressure measurement on commercial HVAC equipment can vary significantly from measuring static pressure on residential equipment. In addition to pressures being higher than most residential equipment, the number and type of pressures measured differ as well. Some commercial equipment is rated by fan pressure as opposed to the total external static pressure listed on smaller equipment. Packaged Equipment Commercial rooftop equipment is probably used the most in commercial applications today in most regions of the country.

Packaged equipment 7.5 tons and larger offer some unique challenges of their own that you should be aware of to avoid erroneous readings. Generally, when measuring total external static pressure, measure the pressure at the point where airflow enters the equipment and where the airflow exits the equipment. The pressure entering the equipment is a suction or negative pressure. The pressure exiting the equipment is a discharge or positive pressure. Add these two pressures together to find the equipment measured total external static pressure. Example: A 10 ton packaged unit in a rooftop application placed on a curb. Equipment entering pressure -.46-in. w.c. Equipment exiting pressure +.51-in. w.c. Total External static pressure .97-in. w.c. Compare the measured static pressure to the equipment rated maximum total external static pressure to assure the system is operating at less than the maximum rated total external static pressure as rated by the manufacturer. Disregard the + and – signs as these represent the type of pressure measured and are not numerical values.

You can also use the measured total external static pressure and the measured fan RPM to plot fan airflow on the manufacturer’s fan performance table or fan curve. Notice that this packaged unit is shipped with the filter and coil included. So to measure total external static pressure of this unit, the coil and filter are included in the equipment total external static pressure measurement. “As shipped” is a term being circulated around the industry recently that brings clarity to static pressure measurement. When considering how to measure total external static pressure and determining if a component of a system should be included or excluded in the total external static pressure reading, determine if the component was included with the equipment “as shipped”. You may still need to check the filter and coil static pressure drops installed in the unit. This is done by inspecting and then drilling test holes on either side of these components through the cabinet of the equipment.

Always be sure to remove panels and inspect before drilling. Then subtract the pressure on either side of the component to find its actual pressure drop. Compare the actual pressure drop of these components to the rated pressure drop at current airflow. If actual pressure drop matches the rated pressure drop, the component is clean. If the actual pressure drop exceeds the rated pressure at the specified airflow, this is an indication the filter or coil may be dirty and need cleaning to improve the performance of the system. Commercial Air Handlers Larger commercial air handlers may be rated with a total external static pressure rating similar to packaged equipment. But built-up or custom made units may also be rated based on fan static pressure. Equipment rated at a specified fan pressure is often done so because a variety of components may be added to the air handlers for specific applications. For example, the basic air handler is built with a fan rated pressure of 3.0-in. w.c, and the manufacturer will publish fan capacities under the tested conditions.

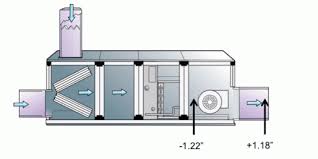

Yet as these units are custom built, a number of accessories may be added to the equipment that would significantly change the total external static pressure of the equipment. So to keep effective engineering data, fan pressure only is used. Air handler accessories may include a DX or cold water coil, a hot water coil, pre-filters for the outside air or perhaps a series of standard and charcoal filters to capture pollutants or a series of HEPA filters for an operating room. Each of these, or a total of all of these accessories will greatly affect the rated total external static pressure of the unit. But if the equipment is rated at fan pressure, fan static pressure can always be measured and interpreted regardless of the number of accessories added to the equipment. Example: A 20 ton air handler unit in a horizontal application is placed in a mechanical room. Fan entering pressure -.1.22-in. w.c. Fan exiting pressure +1.18-in. w.c. Fan operating pressure 2.40-in. w.c.

The fan airflow would then be plotted on the manufacturer’s fan curve as published for the fan pressure. No total external static pressure would be published or referred to in the engineering data since only the fan pressure would be used. Be sure to check the nameplate pressure listing and the published engineering data for each piece of equipment’s pressure rating. You will still find some larger equipment rated using total external static pressure, and others using fan rated pressure. Air Handler Accessory Pressure Drops The pressure drop of each of the accessories (coils and filters) that are added to the air handler can then be measured and compared to the their respective pressure drops rated at the operating airflow. Often static pressure profiles are used to report measured pressure of these commercial air handlers. A static pressure profile is a graphic illustration of the equipment and will include the location of each pressure test and the corresponding pressure reading taken at that point in the system.