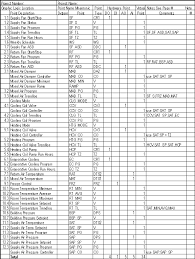

air handling unit control points

Air Handling Unit BMS Control The existing DI/SDI and VRF DX Interfaces use a TA sensor and set-point (via Remote Controller) to maintain Room Air or Return Air temperature. The range has been further expanded by the development of a new DX interface which can directly control capacity, operation and mode from a BMS system. The new DI/SDI and VRF 0-10V AHU DX Interface enables BMS capacity control of Toshiba outdoor units connected to a DX Coil in an Air Handling Unit. The interface is compatible with Toshiba’s range of Digital Inverter, Super Digital Inverter and VRF SMMSi 8HP and 10HP outdoor units. The interface includes a common DX Interface (RBC-DXC031) for both DI/SDI and VRF systems. Default setting is configured to operate in DI/SDI model mode. Configuration for use with a VRF SMMSi system is made by change to DIP Switch settings. Allows connection of 3rd party AHU to all Toshiba DI/SDI and VRF SMMSi outdoor units Controlled via 3rd party BMS Control

Toshiba wired remote controller required for system configuration Control 0~10V PCB Analogue Inputs to operate with Stepped or Linear response This document requires business lounge registration.

discount ac package unitsClick here to login or register.

through wall ac and heat units Volume 55, March 2012, Pages 136–148

air handling unit cost Multivariable robust control of an air-handling unit: A comparison between pole-placement and H∞ controllers Received 26 July 2011, Revised 3 November 2011, Accepted 5 November 2011, Available online 29 November 2011Control of air-conditioner units is essential to achieve satisfactory comfort conditions in buildings while keeping low energy consumption and operation costs. In this paper, a nonlinear multiinput & multioutput model (MIMO) of an air-handling unit (AHU) is considered.

After linearization of the state equations around the operating points, an observer and a regulator are designed for the estimation of state variables and disturbance rejection, respectively. A realistic uncertain model is considered which constitutes various uncertainties associated with complex nonlinear model of AHU. In the presence of model uncertainties, a H∞-robust controller is designed to guarantee robust performance of the air-handling unit. In addition, a simple controller based on pole-placement approach is developed. Indoor temperature and relative humidity are controlled via manipulation of valve positions of air and cold water flow rates. Achievement of tracking objectives is investigated through various desired commands of indoor temperature and relative humidity (including a sequence of steps and ramps-steps). According to results, the H∞-robust controller guarantees the robust performance of the AHU in tracking of desired set-paths (while using the simple pole-placement controller leads to high oscillatory behavior of the output variables and control efforts).

Moreover, using H∞-robust controller results in less energy consumption in comparison with the pole-placement controller.Highlights► Robust control of a multivariable air-handling unit (AHU). ► Controllers designed based on pole-placement and μ-synthesis. ► Robust performance in the presence of model uncertainties. ► Achievement of various tracking objectives in temperature and relative humidity. ► Comfort conditions in buildings with low energy consumption and operation cost.Keywords; ; ; ; Copyright © 2011 Elsevier Ltd. DDC Control Module for an Air Handling Unit – This is a direct digital controls control module for an air handler that serves some VAV boxes in office spaces for a Data Center. This DDC control module includes analog and digital inputs and analog and digital outputs to handle all the control functions necessary to control the devices and components on a large commercial air handler.DDC Control Module for an Air Handling UnitFor example, damper actuators can be either two position or analog modulating.

If the actuator is two position then an a digital output sends a 24 volt signal to the damper actuator to drive the damper open or closed depending on its default position. A modulating actuator damper will get an analog signal from the DDC control module so the damper can modulate as determined by the program and inputs from other devices. For inputs these also can be either digital or analog where something such as a high static pressure switch would be digital so when the switch trips because of high static pressure in the air handler then the digital controller shuts down the air handler. An analog input would be something such as a temperature sensor or pressure transmitter in the duct work. The controller reads the analog signal sent back from these devices, processes these inputs, and then sends a control signal to an output device to control the medium or process.DDC Control Module for an Air Handling UnitThe interface offers a logical way for a programmer or user to understand how the logic in the program works for the DDC control system.

By clicking on the blocks in the program and having the correct privileges one can change the parameters inside the logic blocks. For example, if you want to change the temperature set point for a space or room you would look for the logic block that contains that set point and click on it and change it to the desired set point. With a little training the average operator can learn how to use the DDC system including the DDC interface to maintain maintenance on HVAC equipment, troubleshoot problems with the HVAC system, and monitor temperatures and conditions in the HVAC system.To learn more for HVAC and DDC click here. DDC Logic InterfaceDDC Control Module for an Air Handling Unit Volume 43, Issue 4, April 2011, Pages 805–813 Nonlinear multivariable control and performance analysis of an air-handling unit Received 26 September 2010, Revised 4 November 2010, Accepted 25 November 2010, Available online 3 December 2010To maintain satisfactory comfort conditions in buildings with low energy consumption and operation cost, control of air-conditioner units is required.

In this paper, nonlinear control of an air-handling unit (AHU) is investigated and compared for two control approaches: gain scheduling and feedback linearization. A nonlinear multi input–multi output model (MIMO) of an air-handling unit (AHU) is considered. Both indoor temperature and relative humidity are controlled via manipulation of valve positions of air and cold water flow rates. Using an observer to estimate state variables, a hybrid control system including regulation system for disturbance rejection and nonlinear control system for tracking objectives is designed. Achievement of tracking objectives is investigated for various desired commands of indoor temperature and relative humidity; including a sequence of steps and ramps-steps. According to results, more quick time responses with a bit more overshoot in tracking set-points/paths are achieved by using feedback linearization method (especially for temperature). However, valves position as input control signals are associated with less oscillation (and consequently less energy consumption) when the controller designed based on gain scheduling approach is used.