ac unit receiver

The GPS Receiver R&S®GPS129 has been designed to provide the user with extremely precise time and position data. The R&S®GPS129 consists of a GPS receiver and a satellite-controlled clock together with a power supply unit, all installed in a metal 19" rackmount and ready to operate. It is available with AC or DC power supply. GPS receiver and reference frequency generator combined in a single unit High precision due to GPS-based operation 6 channel C/A code receiver with external antenna/converter unit antenna/converter unit with remote power supply The GPS Receiver R&S®GPS129 has been designed to provide the user with extremely precise time and position data. When it comes to direction finding and location of radio emitters, the exact position of the DF antenna must be known in order to calculate the target location from the bearings and location of two or more direction finders. The R&S®GPS129 provides GPS-based position information via the serial interface.

In addition, the R&S®GPS129 offers high-accuracy 2.048 MHz and 10 MHz frequency outputs to increase the frequency accuracy of receivers if the receiver is fitted with a frequency reference input.It is available with AC or DC power supply. The interfaces and input/output signals provided by the R&S®GPS129 are accessible via connectors on the rear panel. The global positioning system (GPS) is a satellite-based radio positioning, navigation, and time transfer system. GPS is based on accurately measuring the propagation time of signals transmitted from satellites to the receiver. The R&S®GPS129 has been developed for applications where conventional radio-controlled clocks cannot meet the growing precision requirements. High precision available 24 hours a day around the world is the main feature of this unit which receives its information from the satellites of the global positioning system. Compact design: 19" rackmount with a height of just 1 unit for integration into system racks

Suitable for stationary, transportable and mobile applications Available with AC or DC power supply

causes house ac unit freeze up Remote-controlled operation for optimum integration into monitoring systems, especially Spectrum Monitoring and Management System R&S®ARGUS-IT or Coverage Measurement System R&S®ARGUS-FMTV.

how much to replace inside and outside ac unit with known receiver position and valid almanac

charging an air conditioner at home every second on the second (P_SEC, TTL level) every minute on the minute (P_MIN, TTL level) better than ±250 ns after synchronization and 20 minutes of operation better than ±2 µs during the first 20 minutes of operation with GPS-synchronous operation and 2 hours of operation

with GPS-synchronous operation, averaged over 24 h 1 day, free running 1 year, free running Allen Variance (1s, 10s) 1 Hz beside carrier 10 Hz beside carrier 100 Hz beside carrier 1 to 10 kHz beside carrier 9-pin D-Sub connector, serial RS-232-C interface (default setting: 19200, 8N1) 9-pin D-Sub connector, serial RS-232-C interface (default setting: 9600, 8N1) 9-pin D-Sub connector providing TTL inputs for storing time stamps and TTL outputs with pulses every second on the second or every minute on the minute BNC jack, 2.048 MHz reference frequency, 3.0 V pp into 50 Ω BNC jack, 2.048 MHz reference frequency, 3.0 V pp into 25 Ω, switched on when the specified accuracy has been reached BNC jack, 10 MHz reference frequency, 3.0 V pp into 50 Ω BNC jack, 10 MHz reference frequency, 3.0 V pp into 25 Ω, switched on when the specified accuracy has been reached N jack, RF input (GPS antenna/converter unit) model 02: mains connector, 100 V to 240 V AC

model 04: DC connector, 19 V to 35 V DC meets EMC directive of EU (89/336/EEC) and German EMC law developed and manufactured in compliance with ISO 9000 model 02: 100 V to 240 V AC, 50 to 60 Hz, 20 VA model 04: 19 V to 35 V DC, 2 A max./20 W Dimensions (W × H × D) 19" rackmount 1 HU - 483 mm x 44 mm x 345 mmThe most likely cause of an automotive air conditioner cooling problem is no refrigerant in the system. If the refrigerant has escaped past a leaky compressor or O-ring seal, leaked out of a pinhole in the evaporator or condenser, or seeped out through a leaky hose, the leak needs to be identified and repaired before the system is recharged. On many systems, the compressor will not turn on if the refrigerant is low because the "low pressure safety switch" prevents the compressor clutch from engaging if system pressure is low. This protects the compressor from possible damage caused by a lack of lubrication. One of the first things you should check, therefore, is compressor engagement.

If the compressors magnetic clutch is not engaging when the A/C is turned on, the problem may be a blown fuse or a wiring problem. If the fuse is blown, replacing it may restore cooling temporarily. But the underlying reason for the fuse blowing in the first place needs to be identified and corrected to prevent the same thing from happening again. If the magnetic clutch is receiving voltage but is not engaging the compressor, the clutch is defective and needs to be replaced. If there is any evidence of leakage around the compressor shaft seal, the seal should also be replaced. If the clutch works but fails to turn the compressor (the belt may squeal in protest!), the compressor has seized and needs to be replaced. Compressor failures are usually the result of loss of lubrication, which in turn may be due to low refrigerant in the system, a blockage (such as a plugged orifice tube which prevents refrigerant and oil from circulating to the compressor), loss of lubricant due to leaks or improper service procedures (not adding oil to the system to compensate for oil lost through leakage or component replacement)

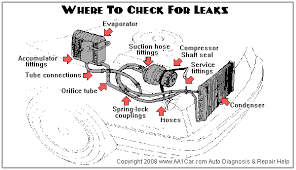

, or use of the wrong type of lubricant. R-12 systems require mineral oil while R-134a systems require various types of PAG oil or POE oil. Using mineral oil in a newer R-134a system can cause serious lubrication problems as can using the wrong grade (viscosity) of PAG oil. Always follow the vehicle or lubricant manufacturers compressor oil recommendations. The next thing you should check when troubleshooting a no cooling problem is system pressure. For this, you need a set of A/C service gauges. Attach your service gauges to the high and low service fittings. If both the high and low side pressure gauges read low, the system is low and needs recharging. But before any refrigerant is added, check for leaks to find out where the refrigerant is going. All vehicles leak some refrigerant past seals and through microscopic pores in hoses. The older the vehicle, the higher the rate of seepage. Newer vehicles have better seals and barrier style hoses so typically leak less than a few tenths of an ounce of refrigerant a year.

But system capacities also tend to be smaller on newer vehicles, so any loss of refrigerant will have more of an adverse effect on cooling performance. Various methods can be used to check for leaks. The telltale oil stains and wet spots that indicate leaks on older R-12 systems are less apparent on the newer R-134a systems because PAG lubricants are not as "oily" as mineral oil. This makes it harder to see leaks. Leaks can be found by adding special dye to the system (available in pressurized cans premixed with refrigerant), an electronic leak detector, or plain old soapy water (spray on hose connections and watch for bubbles -- requires adding some refrigerant to system first and turning the A/C on). Once you've found a leak, repairs should be made prior to fully recharging the system. Most leak repairs involve replacing O-rings, seals or hoses. But if the evaporator or condenser are leaking, repairs can be expensive. Diagnosing an A/C cooling problem is best done by connecting a gauge set to the high and low pressure service fitting on the system.

Though poor cooling is often due to a low charge of refrigerant, it can also be caused by many other factors (see chart above). How to tell if your A/C system needs refrigerant: look at the LOW pressure gauge reading when the engine is OFF. On an 80 degree day, the LOW gauge should read about 56 psi or higher if the A/C system contains an adequate charge of refrigerant. On a 90 degree day, the LOW side reading should be about 70 psi or higher. If the LOW gauge reading is less than this, the A/C system probably needs some additional refrigerant. Refer to the vehicle manufacturer specifications for normal system operating pressures, and the total refrigerant capacity of the system. Most newer passenger car A/C systems do not hold much refrigerant (14 to 28 oz.), so you don't want to add too much if the system is low. An A/C system that blows cold air for awhile then warm air is probably freezing up. This can be caused by air and moisture in the system that allows ice to form and block the orifice tube.

Evacuating the system with a vacuum pump will purge it of unwanted air and moisture. Evacuation should be done with a vacuum pump that is capable of achieving and holding a high vacuum (29 inches) for at least 30 to 45 minutes. For best performance, an A/C system should contain less than 2% air by weight. For every 1% increase in the amount of air that displaces refrigerant in the system, there will be a corresponding drop of about one degree in cooling performance. More than 6% air can cause a very noticeable drop in cooling performance, and possibly cause evaporator freeze-up. Air can get inside a system through leaks, by not evacuating the system prior to recharging it, and/or by recharging the system with refrigerant that is contaminated with air. Recovery equipment can suck air into the recycling tank if an A/C system contains air or if the system has a leak. For this reason, the refrigerant recovery tank on recycling equipment must be checked and purged daily. On some equipment, this is done automatically.

But on equipment that lacks an automatic purge cycle, tank pressure and temperature has to be measured and compared to a static pressure reference chart. Some refrigerant identifier equipment can detect air in the system as well as other contaminants. An identifier should be used to check the refrigerant before the system is serviced to prevent cross-contamination of recovery and recycling equipment. Possible causes of intermittent cooling in a manual A/C system that might be caused by an electrical problem include: Faulty low pressure cutout switch. This switch prevents the compressor from running if the refrigerant level is low. If the cutout switch is not reading correctly, it can prevent the compressor from coming on.The magnetic clutch on the compressor requires full battery voltage to engage. If the voltage to the clutch is low, or the clutch coils have too much resistance, or the air gap in the clutch is too great, the clutch may not engage to drive the compressor.

Faulty compressor clutch relay. Check to see if the relay is receiving voltage when the A/C is turned on. Also check the relay wiring and ground connections. If bypassing the relay with a jumper wire or routing battery voltage directly to the compressor clutch makes the A/C work, the relay is probably bad. Faulty A/C control switch. The switch may be worn and not making good contact when it is turned on. Some possible causes of intermittent cooling (or no cooling) on automatic A/C systems include all of the above, plus: A problem in the control module or control head (this usually requires using a dealer scan tool to read fault codes and perform self-diagnostics). A bad temperature sensor (an ambient air temperature sensor, interior air temperature sensor, evaporator temperature sensor, or sunload sensor). Again, a factory scan tool is usually required to perform diagnostics on the system. Noise from the compressor usually means the compressor is on its way out.