ac motor control drive

Allen-Bradley® Drive Software provides a basic Windows® Internet Explorer®-style interface for easy online programming, maintenance, and troubleshooting of your PowerFlex® drives. Drive software is available in a variety of configurations to meet your application needs. Connected Components Workbench Software Drives, AC Low Voltage The PowerFlex® family of AC drives offers a broad range of control modes, features, options, and packaging, as well as global voltages and many power ratings. With a consistent programming structure and common operator interface, PowerFlex drives ease programming and configuration, and they reduce set-up time, training, and operation. PowerFlex Compact Class AC drives deliver a cost-effective, general-purpose solution for standalone machine level control applications and simple system integration. PowerFlex Architecture Class AC drives provide a broad set of features and application-specific parameters, and they are ideal for high-performance applications.

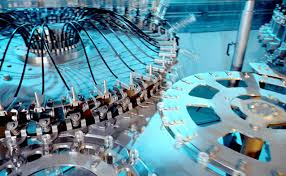

Drives, AC Medium Voltage PowerFlex® 7000 Medium Voltage Drives enable soft-starting and variable-speed control of processes with high power demands.

how many air conditioning units are sold each yearThey help reduce energy costs, component count, maintenance and motor wear.

how to replace ac unit PowerFlex 6000 Medium Voltage AC Drives

how to install wall ac unit PowerFlex 7000 Medium Voltage AC Drives PowerFlex 7000 Drive System with ArcShield Technology PowerFlex® drives are motor control solutions that efficiently handle applications from low to medium voltage and from simple to highly demanding. These drives feature hardware, software and safety options. We also have industrial motors for optimum variable speed performance and service life.

Our servo drive portfolio includes a wide variety of products that offer the right size and feature set to handle a broad range of applications. From single axis component drives to multi-axis modular drives, we offer solutions designed to help you simplify machine design while improving system performance. Our Integrated Motion drives fit seamlessly into the Logix platform for easy use and plug-and-play configurability. Network options and a choice of safety features are available. Kinetix Integrated Motion on EtherNet/IP Kinetix Indexing and Component Kinetix Integrated Motion on SERCOS Our Industrial Motors are high quality and stand up to exceptional conditions such as the extreme thermal and electrical demands of low-speed high-torque applications. We have a wide selection of general-purpose and vector motors with NEMA Premium Efficient designs and optimum variable speed performance and service life. We also have durable motors for use in harsh environments.

Servo Motors include a broad portfolio of Rotary Motors and Linear Motors. Our rotary motors comprise several series including the VP Low-inertia motors, the MP-Series™ of stainless steel, food grade, medium-inertia and low-inertia options, and the HPK-Series™ High-Power motors. Our linear motors include the LDC-Series™ and LDL-Series™ with no-wear. The servo motor families offer Smart Motor Technology to provide automatic identification of correct motor-to-drive connectivity.Site ExplorerClose site explorer Did this information help you?yesnoHome > Publishers > AIP Conference Proceedings > PROCEEDINGS OF THE SIXTH GLOBAL CONFERENCE ON P… > This paper aims to investigate the performance of ABB ACS800 variable speed drive operating under Scalar Control mode, and eventually develop a set of experimental procedures for undergraduate laboratory purposes. Scalar Control is the most widespread form of ac drive, for its low cost and simplicity especially implemented in the open loop mode.

Scalar control is achieved by controlling the stator voltage and frequency, thus maintaining the motor's air-gap flux at a constant value. To illustrate the control method, the ac drive is configured according to the wiring diagram in the firmware manual that the drive control location can be both local and external. The drive is selected to operate under Factory application macro, whereby either ordinary speed control applications or constant speeds applications may be used. Under ordinary speed control, frequency reference signals are provided to the drive through the analogue input AI1. The drive will operate at the given frequency reference value throughout the operation regardless of any changes in the load. The torque speed curve moves along the speed axis with no changes to the shape as the supply frequencies changes. On the other hand, the drive allows three preset constant speed through digital inputs DI5 and DI6. The drive operate at a constant speed value over a time period, and only switch from one constant speed to another constant speed by triggering the two input switches.

Scalar control is most suitable for applications not required high precision, such as blowers, fans and pumps. MOST READ THIS MONTH MOST CITED THIS MONTH Periodic table for topological insulators and superconductors The FLUKA code: description and benchmarking Analysis of positron profiling data by means of ‘‘VEPFIT’’ Data & Media loading...AC motor drives are defined as amplifiers or frequency inverters that interface between a controller and an AC motor. They convert step and direction input from the controller to currents and voltages compatible with the motor. These units are sometimes called variable frequency drives, referring to a majority of AC motor drives which adjust input frequency. In industry, a 'drive controller' is a motor drive which incorporates functions of a controller and drive to determine the speed, torque, horsepower, and direction of an AC motor. AC motors tend to require less maintenance than DC motors, making them preferable for hard-to-service locations.

They are better suited for high speed operation since no brushes are involved and commutation is not a problem. They are also generally smaller, lighter, and more commonly available than DC motors. View Teardown of ABB ACS150 1 HP AC Motor Drive AC motor drives are classified based on the type of AC motor being used. The most common types include induction, synchronous, sensorless vector, and servo drives. Induction motors derive their name from the fact that current is induced into the rotor windings without any physical connection with the stator windings (which are directly connected to an AC power supply); adaptable to many different environments and capable of providing considerable power as well as variable speed control. Typically there is "slip," or loss of exact speed tracking with induction motors. Synchronous motors operate at constant speed up to full load. The rotor speed is equal to the speed of the rotating magnetic field of the stator; there is no slip.

Reluctance and permanent magnet are the two major types of synchronous motors. A synchronous motor is often used where the exact speed of a motor must be maintained. Sensorless vector drives employ independent control of both the voltage and frequency supplied to the motor for good speed control, and low-speed torque output approaching that of DC motors. Sensorless indicates that no feedback sensor such as an encoder or resolver is used. Servo motors are typically permanent magnet synchronous motors that can often have low torque-to-inertia ratios for high acceleration ratings. They frequently employ brushless commutation with feedback provided by Hall Effect sensors, and sinusoidal winding excitation. AC motor drives can also be classified based on types of control functions (e.g. integral motion controllers, variable speed drives, motor speed controllers, etc.). There are a wide range of design specifications to consider when searching for AC motor drives. The most important of these include: